и®ІйўҳдёҖпјҡйҖҡиҝҮеҸҜеӣһ收жқҗж–ҷзҡ„дҪҝз”ЁжқҘеҮҸе°‘зўіи¶іиҝ№зҡ„TPEеә”з”Ёж–№жЎҲВ

Reducing Your CO2 Footprint using TPE with Recycled Content

дёӯж–Үз®Җд»Ӣ

зғӯеЎ‘жҖ§еј№жҖ§дҪ“(TPE)иў«еә”з”ЁдәҺеҗ„зұ»иҪҜи§Ұж„ҹеә”з”ЁйўҶеҹҹпјҢеҰӮпјҡеә”з”ЁдәҺе»әзӯ‘&е»әжқҗе’Ң科жҠҖеә”з”Ёзҡ„еҜҶе°Ғ件пјҢж¶Ҳиҙ№е“Ғе’ҢжұҪиҪҰзҡ„иҪҜи§Ұж„ҹеә”з”ЁйғЁд»¶гҖӮеҜ№дәҺиҝҷз§Қеә”з”Ёзҡ„жқҗж–ҷпјҢйҡҫд»Ҙд»Һй«ҳжҖ§иғҪзҡ„гҖҒжҢҒз»ӯжҖ§зҡ„еҸҜеӣһ收иө„жәҗдёӯеҫ—еҲ°иҪҜжҖ§еҸҜеӣһ收еҺҹжқҗж–ҷгҖӮ

жңҖж–°зҡ„TPEдҪҝз”ЁдәҶпјҢйҖҡиҝҮжңәжў°жҲ–иҖ…еҢ–еӯҰеӣһ收方法еҫ—еҲ°зҡ„е·Ҙдёҡеӣһ收(PIR)жҲ–ж¶Ҳиҙ№еҗҺеӣһ收(PCR)зҡ„еӣһ收жқҘжәҗзҡ„жқҗж–ҷдҪңдёәеӣһ收жҲҗеҲҶгҖӮйҖҡиҝҮеҸҜеӣһ收еҲ©з”Ёжқҗж–ҷзҡ„дҪҝз”ЁпјҢиҜёеҰӮжұҪиҪҰеҶ…йҘ°еһ«гҖҒеүғйЎ»еҲҖжүӢжҹ„зҡ„еә”з”ЁйғЁд»¶зҡ„дәҢж°§еҢ–зўізўіи¶іиҝ№еҸҜд»Ҙеҫ—еҲ°жҳҫи‘—зҡ„еҮҸе°‘гҖӮ

В English Description

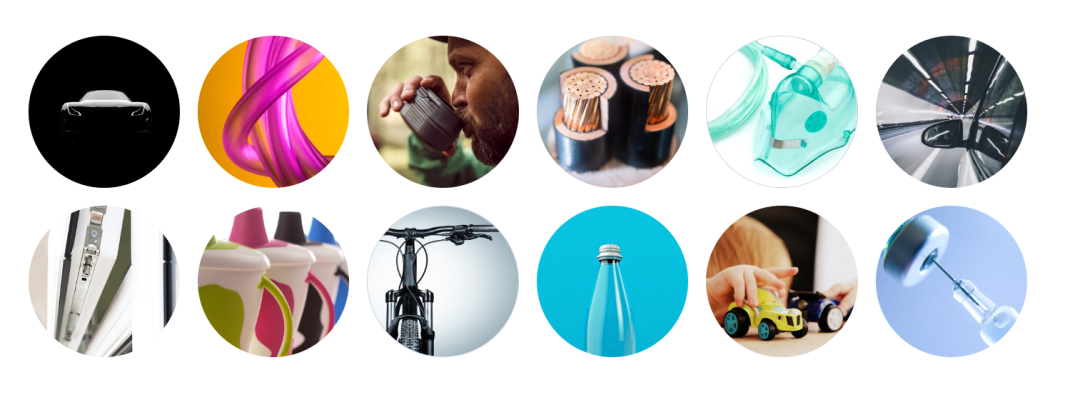

Since a few years an important trend is to reduce odour and emission in car interiors. New Thermoplastic Elastomers (TPE) can reduce those values even while using recycled raw materials. Those reduce the CO2 footprint which is another target of most OEMs. Currently PVC and PU materials are mostly used for interior surfaces but cannot be recycled. New TPE materials combine pleasant haptics with highest scratch resistance and can be recycled with polypropylene carriers. Many OEM are also looking into TPE as an alternative to classic rubber materials as temperature requirements in BEVs are reduced and TPE materials allow recyclability, lower process costs and multicomponent processing with other thermoplastics

ж—Ҙжңҹпјҡ

ж—¶й—ҙпјҡ

ең°зӮ№пјҡ

Serving Automotive Trends with New TPE DevelopmentssВ

дёӯж–Үз®Җд»Ӣ

иҝ‘е№ҙжқҘпјҢеҮҸе°‘иҪҰеҶ…ж°”е‘іе’Ңжңүе®іжҺ’ж”ҫжҲҗдёәдәҶдёҖдёӘйҮҚиҰҒзҡ„и¶ӢеҠҝгҖӮеҚідҪҝдҪҝз”ЁеҸҜеӣһ收зҡ„еҺҹжқҗж–ҷпјҢж–°еһӢзғӯеЎ‘жҖ§еј№жҖ§дҪ“(TPE)д№ҹеҸҜд»ҘйҷҚдҪҺе…¶зӣёеә”зҡ„ж•°еҖјгҖӮеҮҸе°‘CO2зўіи¶іиҝ№жҳҜеӨ§йғЁеҲҶOEMеҺӮе•Ҷзҡ„еҸҰдёҖдёӘзӣ®ж ҮгҖӮзӣ®еүҚпјҢPVCе’ҢPUжқҗж–ҷиў«е№ҝжіӣзҡ„еә”з”ЁдәҺжұҪиҪҰеҶ…йҘ°иЎЁйқўпјҢдҪҶ他们жҳҜдёҚеҸҜеӣһ收зҡ„гҖӮж–°еһӢTPEжқҗж–ҷз»“еҗҲдәҶиүҜеҘҪзҡ„жҢүеҺӢи§Ұж„ҹд»ҘеҸҠжһҒй«ҳзҡ„жҠ—еҲ®ж“ҰжҖ§иғҪпјҢеҗҢж—¶еҸҜд»ҘдёҺеә•еұӮPPйӘЁжһ¶дёҖеҗҢеӣһ收гҖӮеӣ дёәзәҜз”өеҠЁжұҪиҪҰ(BEV)еҜ№дәҺжқҗж–ҷзҡ„иҖҗжё©иҰҒжұӮйҷҚдҪҺпјҢеҠ дёҠTPEжқҗж–ҷзҡ„еҸҜеӣһ收жҖ§гҖҒеҠ е·Ҙе·ҘиүәжҲҗжң¬зҡ„йҷҚдҪҺд»ҘеҸҠеҸҜд»Ҙе’Ңе…¶д»–зғӯеЎ‘жҖ§еЎ‘ж–ҷиҝӣиЎҢе…ұжҢӨжҲ–з»“еҗҲеҠ е·Ҙзҡ„зү№жҖ§пјҢзӣёеҪ“дёҖйғЁеҲҶOEMеҺӮе•Ҷд№ҹе°Ҷзӣ®е…үжҠ•жіЁдәҺTPEпјҢе°Ҷе…¶дҪңдёәдј з»ҹж©Ўиғ¶зҡ„жӣҝд»Јжқҗж–ҷгҖӮ

В English Description

Since a few years an important trend is to reduce

odour and emission in car interiors. New Thermoplastic Elastomers (TPE) can

reduce those values even while using recycled raw materials. Those reduce the

CO2 footprint which is another target of most OEMs. Currently PVC and PU

materials are mostly used for interior surfaces but cannot be recycled. New TPE

materials combine pleasant haptics with highest scratch resistance and can be

recycled with polypropylene carriers. Many OEM are also looking into TPE as an

alternative to classic rubber materials as temperature requirements in BEVs are

reduced and TPE materials allow recyclability, lower process costs and

multicomponent processing with other thermoplastics.

ж—Ҙжңҹпјҡ

ж—¶й—ҙпјҡ

ең°зӮ№пјҡ

We are everywhereжҲ‘们е°ұеңЁжӮЁиә«иҫ№